Intel’s highly anticipated Panther Lake processors may be facing significant delays, raising concerns about the company’s ability to compete at the cutting edge of semiconductor technology. Analyst Ming-Chi Kuo has reported that early 2025 production yields remain below 30%, forcing widespread availability to slip into 2026. While Intel officially maintains that Panther Lake remains on schedule for a second-half 2025 launch, these manufacturing hurdles suggest that real consumer availability could be significantly limited.

The 18A Process Bottleneck: Intel’s Big Gamble

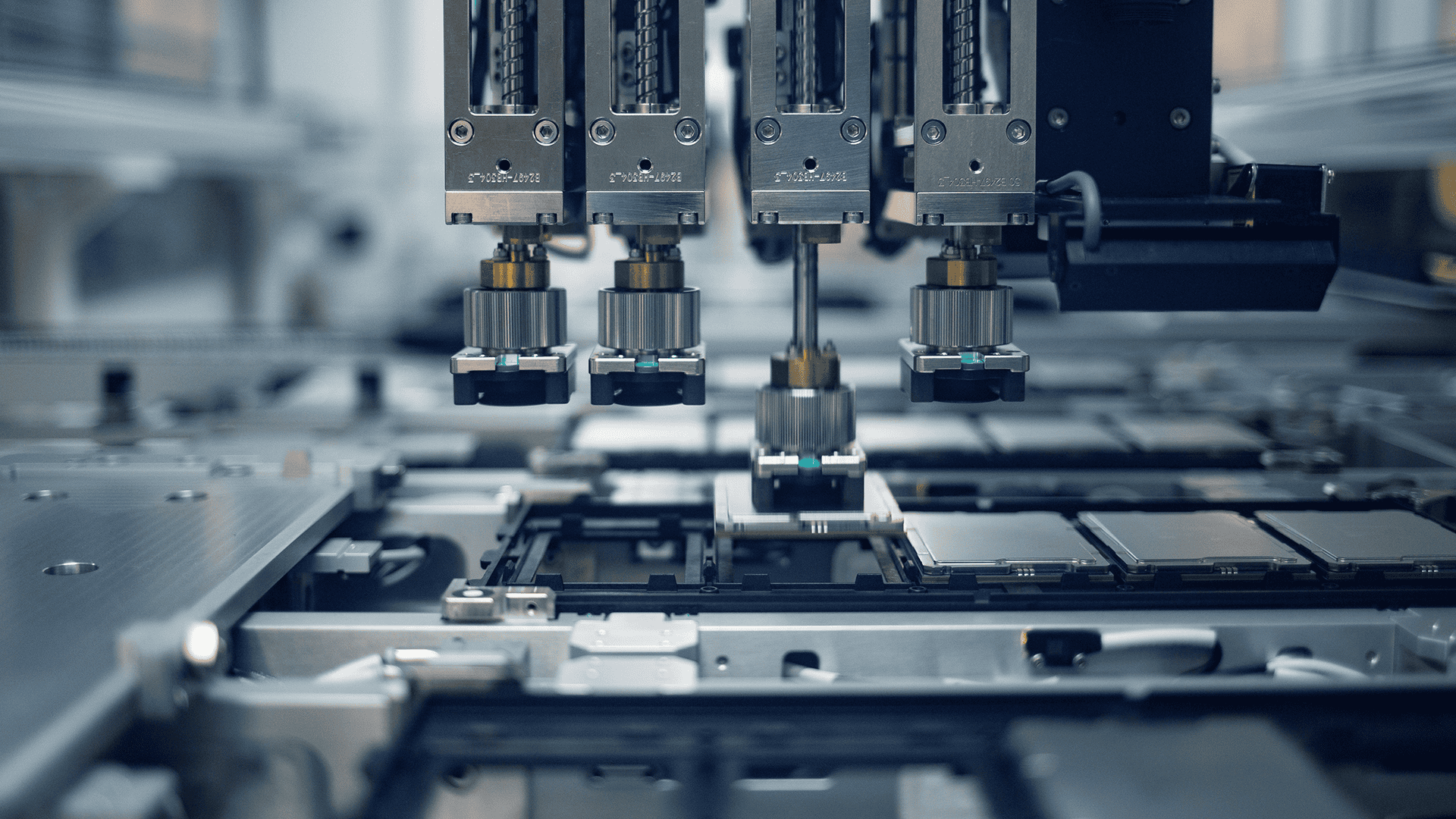

The key culprit behind the delay is Intel’s ambitious 18A manufacturing process—a next-generation node aimed at reclaiming leadership from TSMC and Samsung Foundry. The 18A (1.8nm) process node is Intel’s attempt to leapfrog competitors by introducing RibbonFET transistors and PowerVia backside power delivery, both of which promise substantial efficiency gains. However, these advanced techniques also introduce unprecedented manufacturing complexity, leading to the low yield rates that now threaten Panther Lake’s production timeline.

This delay puts Intel at risk of missing the crucial holiday season of 2025, when PC makers typically release new models to capitalize on peak consumer demand. Historically, Intel has dominated this period with major launches, but missing this window could hurt sales and brand momentum—especially as AMD and Qualcomm make aggressive moves in the AI PC space.

A Ripple Effect Across the PC Market

Intel’s struggles with 18A could have broader implications for the laptop and desktop industry, as OEM partners like Dell, HP, and Lenovo may be forced to delay new high-performance models. If Panther Lake-based laptops don’t ship until early 2026, major PC manufacturers may have to rely longer than expected on Arrow Lake and Raptor Lake Refresh platforms, potentially leaving them at a disadvantage against AMD’s Zen 5 and Apple’s M3/M4-series chips.

Additionally, the AI PC market is heating up, with Qualcomm’s Snapdragon X Elite and AMD’s Strix Point chips promising massive leaps in AI-driven performance. Intel’s Panther Lake delay could give these rivals a head start in AI-accelerated computing—a segment Intel has been aggressively marketing but may now struggle to dominate.

What Comes Next for Intel?

In an effort to mitigate the delay, Intel is expected to:

- Accelerate 18A yield improvements by refining its production techniques, possibly through external partnerships with third-party fabs.

- Rely on Arrow Lake (Intel 20A process) to bridge the gap, though it lacks the next-gen AI acceleration features Panther Lake is expected to bring.

- Push for early qualification samples (QS) of Panther Lake to be available in late Q3 2025, allowing select OEMs to release premium high-end models ahead of mass production.

Despite these efforts, if mass production slips further into Q1 2026, Intel could find itself on the defensive against AMD’s upcoming Zen 5 X3D chips, which are expected to deliver best-in-class efficiency and gaming performance.

Final Thoughts: A Critical Moment for Intel

Intel’s 18A delay isn’t just about one chip—it’s a test of whether Intel can successfully execute its comeback strategy. CEO Pat Gelsinger has repeatedly emphasized Intel’s “five nodes in four years” roadmap, but any further delays could shake investor confidence and allow competitors to widen their lead.

As the semiconductor industry races toward smaller, more efficient nodes, the success (or failure) of Panther Lake and 18A will shape the future of Intel for years to come. If Intel manages to stabilize production and hit reasonable yields, it could regain its position as a technology leader. If not, AMD, Apple, and Qualcomm may further erode Intel’s dominance in high-performance computing.

For now, Panther Lake remains a high-stakes gamble—one that could define Intel’s trajectory in the post-2025 era.

Key Takeaways

- Intel’s Panther Lake processors face production delays with yields below 30%, pushing widespread availability into late 2025 or early 2026.

- The 18A manufacturing process is still on track but facing significant yield challenges that affect product timelines.

- Despite setbacks, Intel continues to position Panther Lake as its flagship product for demonstrating next-generation manufacturing capabilities.

Intel’s Manufacturing and Process Technology Advances

Intel’s path to regaining competitive edge in chip manufacturing hinges on its advanced process technologies, particularly the 18A node. The company faces several challenges as it works to ramp up production capabilities while managing delays in key product lines.

Panther Lake Delay and the 18A Technology Node

Intel’s Panther Lake processors, initially targeted for mid-2025, are now expected to arrive in Q4 2025. This delay stems from challenges in scaling the 18A process technology. The 18A node represents a critical advancement in Intel’s manufacturing capabilities, featuring enhanced transistor designs and improved power efficiency.

Testing of the 18A process is currently underway, with major companies like Nvidia and Broadcom participating in early validation. These tests are crucial for identifying and resolving technical issues before full production begins.

Despite the postponement for consumer products, Intel maintains that its server-focused Xeon processors using the same technology are still on track. The typical 2-4 week gap between chip production and finished product shipments suggests Panther Lake products might not be widely available until early 2026.

The Impact on Intel’s Revenue and Operating Margin

The production delays will likely affect Intel’s financial performance through 2025. With competitor AMD gaining market share, Intel faces pressure to deliver its advanced chips on schedule to maintain revenue targets.

Intel’s Q4 results beat estimates, but the company offered weak Q1 guidance, reflecting the manufacturing challenges. The slower-than-expected ramp of the 18A node will impact production capacity and potentially limit Intel’s ability to meet market demand.

Production issues create a ripple effect across Intel’s product lines. Each quarter of delay means:

- Reduced competitive positioning

- Postponed revenue recognition

- Higher manufacturing costs during the transition

These factors collectively strain Intel’s operating margins as the company continues investing heavily in manufacturing advancements while managing the extended timeline for returns.

Comparison With TSMC’s Manufacturing Progress

Intel’s 18A process technology aims to bring the company technologically abreast with TSMC, currently the industry leader in advanced chip manufacturing. TSMC has maintained a consistent edge in process technology for several years.

While Intel works through its 18A challenges, TSMC continues advancing its own manufacturing capabilities. The competitive gap remains significant, with many major chip designers including AMD and Apple relying on TSMC’s proven processes.

Intel’s foundry strategy involves attracting external customers like Nvidia and Broadcom. Success with these partnerships is crucial for validating Intel’s manufacturing capabilities and generating additional revenue streams.

The timeline adjustment for the 18A ramp indicates Intel is prioritizing quality and yield over strict adherence to previously announced schedules. This approach may benefit long-term competitiveness but creates short-term challenges in matching TSMC’s manufacturing efficiency and capacity.

Intel’s Financial Outlook and Strategic Funding Initiatives

Intel faces financial challenges as Panther Lake’s delay affects their 2025 revenue projections, but strategic investments and government funding provide some stability for their long-term roadmap.

Earnings Call Insights and Client Computing Group Performance

Intel’s most recent earnings call revealed mixed results for Q4 2024. The Client Computing Group (CCG), which handles consumer processors, showed modest growth of 3% year-over-year despite supply chain challenges. Revenue reached $8.3 billion, slightly below analyst expectations.

The delay of Panther Lake to Q4 2025 is expected to impact CCG revenue projections for the coming year. Intel’s CFO acknowledged this challenge during the call, noting that the 18A process delays would create a “temporary gap” in their product lineup.

Current Arrow Lake processors continue to perform well in the market, but Intel faces increased competition from AMD’s Zen 5 architecture. The company has adjusted its financial guidance for 2025, reducing expected revenue by approximately 5-7% compared to previous projections.

Investment in Future Technologies: Nova Lake and Arrow Lake

Intel continues to invest heavily in its future product stack despite Panther Lake’s setbacks. The company confirmed that Nova Lake, planned for 2026, remains on schedule as it will use a more mature version of the 18A process technology.

Current investments include:

- $3.5 billion for 18A process refinement

- $2.8 billion for Arrow Lake production optimization

- $1.7 billion for EUV lithography equipment

Intel’s leadership emphasized that Arrow Lake processors will receive extended support and optimization updates to bridge the gap until Panther Lake arrives. This strategy aims to maintain market share while the company works through its manufacturing challenges.

Analysts note that these investments are crucial for Intel’s long-term competitiveness but place short-term pressure on profit margins.

Benefiting From Chips Act Funding and Government Support

The CHIPS Act continues to provide significant financial support for Intel’s manufacturing ambitions. The company has secured $8.5 billion in direct funding and an additional $11 billion in tax credits for its U.S. fabrication facilities.

This government support helps offset some of the financial strain caused by the Panther Lake delay and 18A yield issues. Intel is using these funds to:

- Expand capacity at existing fabs in Arizona and Ohio

- Accelerate R&D for process technology improvements

- Train specialized workforce for advanced manufacturing

The funding specifically designates resources for critical technology development, including the troubled 18A node. Intel’s CEO noted that this support “provides stability during a challenging transition period” and helps maintain the company’s aggressive roadmap despite current difficulties.

Frequently Asked Questions

Intel’s Panther Lake processors face significant delays into late 2025, creating ripple effects across the industry. These challenges center around manufacturing difficulties with Intel’s advanced 18A process technology.

What are the reasons for the delay of Intel Panther Lake processors?

The primary reason for the Panther Lake delay is production issues with Intel’s 18A manufacturing process. According to reports, production yields remain below 30% even in early 2025.

Low yield rates mean that many produced chips fail quality tests, making mass production difficult and costly.

The complex transition to more advanced manufacturing technology has created unexpected technical hurdles that Intel is still working to overcome.

How will the delay in Panther Lake’s release impact Intel’s market strategy?

The push to mid-Q4 2025 forces Intel to rely on older product lines longer than planned. This extends the lifecycle of current offerings while competitors potentially gain market share.

Intel may need to adjust pricing strategies for existing products to maintain competitiveness during this extended transition period.

The delay could affect investor confidence, as Intel has already faced criticism for previous roadmap adjustments and product cancellations.

What measures is Intel taking to address the 18A ramp-up challenges?

Intel is likely putting significant engineering resources toward improving the 18A process yield rates. The company has confirmed that some select customers have already powered on Panther Lake E0 engineering samples.

This suggests Intel is working closely with key partners to identify and resolve issues before mass production.

Intel may also be refining its manufacturing processes and equipment to improve consistency and reliability.

When was Intel initially planning to release Panther Lake CPUs, and how has the timeline changed?

Intel had not publicly confirmed an exact release date, but industry analysts expected Panther Lake to launch in early-to-mid 2025. The reported delay pushes this timeline to mid-Q4 2025.

With the current yield issues, some analysts like Ming-Chi Kuo suggest that Panther Lake notebooks might not become widely available until 2026.

This represents a shift of approximately 6-9 months from the original expected timeline.

What implications does the Panther Lake delay have for PC manufacturers and consumers?

PC manufacturers will need to extend their current product cycles or find alternative solutions. This may disrupt planned product refreshes and marketing campaigns.

Consumers seeking the latest technology will need to wait longer for Panther Lake-powered devices. The gap between chip production and finished product availability typically adds 2-4 weeks.

The delay might cause some manufacturers to pivot to competing solutions for their high-end products.

How does the postponement of Panther Lake compare to previous Intel product launch delays?

This delay follows a pattern of challenges Intel has faced with recent process node transitions. The company has previously adjusted its roadmap for other processor generations.

Intel appears to be taking a more cautious approach with Panther Lake after facing criticism for rushing previous products to market before manufacturing was fully stable.

The 18A process represents one of Intel’s most ambitious manufacturing jumps, making this delay part of a larger restructuring as the company works on a years-long turnaround strategy.