Microchips are the backbone of modern technology, powering everything from smartphones to spacecraft. These tiny marvels of engineering are created through a complex manufacturing process that transforms simple silicon into sophisticated integrated circuits. The microchip manufacturing process involves hundreds of steps and can take up to four months from design to mass production.

The journey of a microchip begins with silicon crystals, which are grown into cylindrical ingots and sliced into thin wafers. These wafers serve as the foundation for the intricate patterns of transistors and other components that make up a microchip. The creation process involves several key stages, including photolithography, etching, and deposition, all carried out in highly controlled cleanroom environments.

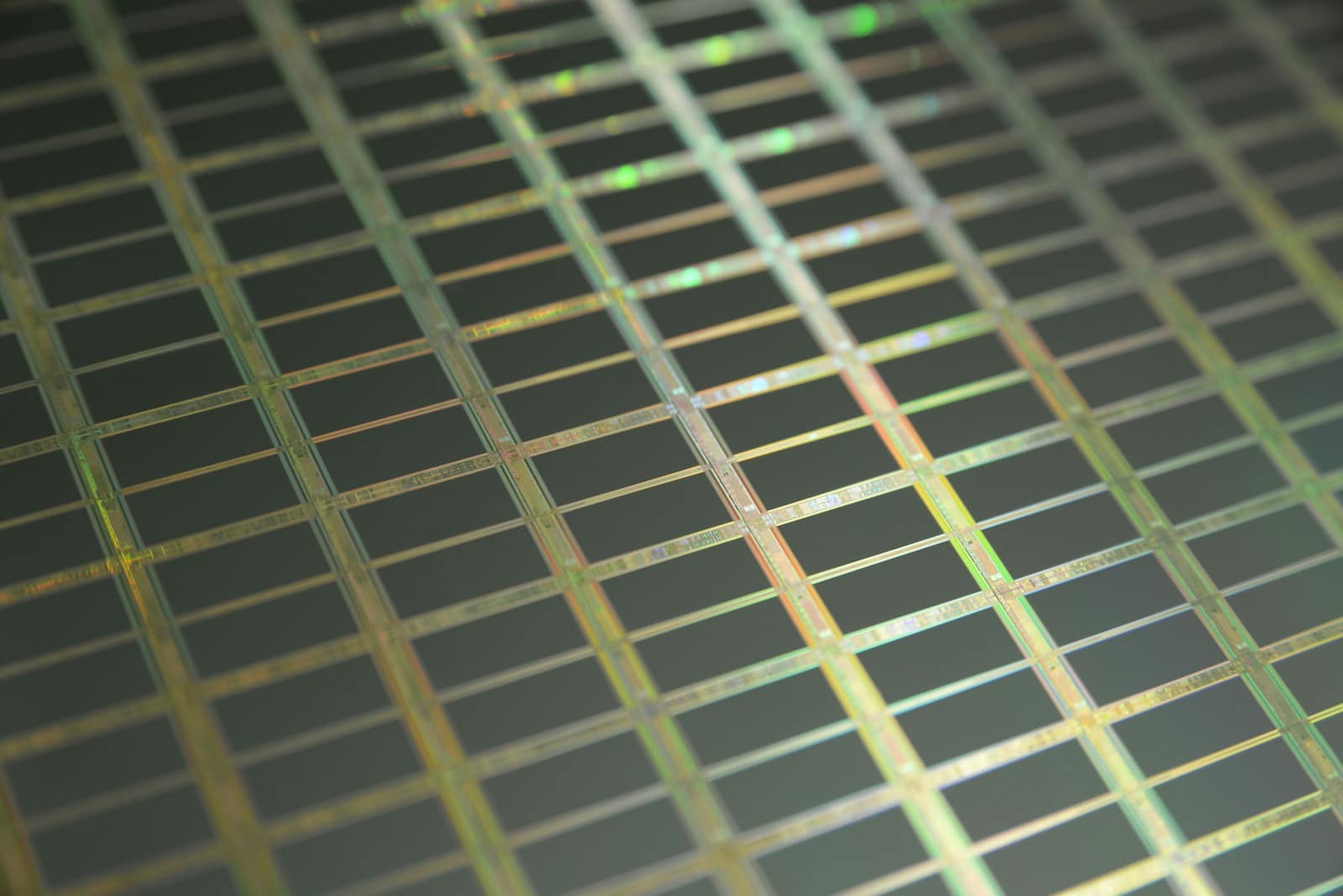

Chipmakers use specialized equipment to build up layers of interconnected patterns on the silicon wafer. This process requires extreme precision, as modern microchips can contain billions of transistors in an area smaller than a fingernail. The final steps involve cutting the wafer into individual chips, testing each one for functionality, and packaging them for use in electronic devices.

Unraveling the Wonders of Microchip Creation

Microchips are the tiny brains powering our modern world. They’re in everything from smartphones and laptops to cars and refrigerators. But how are these intricate components made? Let’s take a closer look at the fascinating and complex process of microchip manufacturing.

From Sand to Silicon

It all starts with sand, which contains silica. The silica is purified into silicon, a semiconductor material. This silicon is then grown into cylindrical ingots, which are sliced into thin wafers. These wafers become the foundation for building microchips.

Photolithography: Printing the Circuit

The intricate circuitry of a microchip is created using a process called photolithography. This involves coating the wafer with a light-sensitive material called photoresist. A pattern is then projected onto the wafer, exposing certain areas of the photoresist. The exposed areas are washed away, leaving behind the desired pattern.

Etching and Doping

The exposed areas of the wafer are then etched away, creating the physical features of the microchip. This is followed by a process called doping, where impurities are introduced into the silicon to change its electrical properties. This creates the transistors and other components that make up the microchip’s circuitry.

Layering and Testing

The process of photolithography, etching, and doping is repeated multiple times to create the multiple layers of a microchip. Each layer adds another dimension to the circuitry. After the layers are complete, the wafer is tested to ensure functionality.

Dicing and Packaging

The wafer is then diced into individual microchips. Each chip is packaged to protect it and provide connection points for it to be integrated into a larger device.

The Importance of Precision

Microchip manufacturing requires incredible precision. The features on a microchip are incredibly small, often measured in nanometers. This requires highly specialized equipment and cleanroom environments to prevent contamination.

The Future of Microchips

The demand for smaller, faster, and more powerful microchips continues to grow. Researchers are constantly developing new materials and manufacturing techniques to push the boundaries of microchip technology. This includes advancements like extreme ultraviolet lithography (EUV) and new transistor designs.

Microchip Manufacturing: A Global Effort

Microchip manufacturing is a complex global industry. Different companies specialize in different aspects of the process, from designing the chips to manufacturing the equipment to fabricating the final product.

Key Players in the Microchip Industry

| Company | Specialization |

|---|---|

| Intel | Chip design and manufacturing |

| TSMC | Chip manufacturing |

| ASML | Lithography equipment |

| Samsung | Memory chips and manufacturing |

| Qualcomm | Mobile chip design |

The Impact of Microchips on Society

Microchips have revolutionized our lives. They have enabled the creation of powerful computers, smartphones, and countless other devices that we rely on every day. The continued advancement of microchip technology promises to bring even more innovation and change in the years to come.

The Environmental Impact of Microchip Production

While microchips bring many benefits, it’s important to consider the environmental impact of their production. Manufacturing microchips requires significant amounts of energy and water. It also produces hazardous waste. The industry is working to reduce its environmental footprint through initiatives like recycling and using renewable energy sources.

Key Takeaways

- Microchip production is a multi-step process that transforms silicon into complex integrated circuits

- The manufacturing process requires specialized equipment and highly controlled environments

- Modern microchips contain billions of transistors in a tiny area, enabling powerful computing capabilities

Foundational Elements of Microchip Fabrication

Microchip fabrication relies on several key processes and materials. These elements work together to create the intricate structures that power modern electronics.

Semiconductor Materials and Silicon Wafers

Silicon wafers form the base for most microchips. Manufacturers create these wafers from high-purity silicon ingots. They slice the ingots into thin, circular discs.

The wafers undergo polishing to achieve an ultra-smooth surface. This smoothness is crucial for the subsequent fabrication steps.

Silicon’s semiconductor properties make it ideal for chip production. It can be easily doped with other elements to alter its electrical characteristics.

Other semiconductor materials like gallium arsenide see use in specialized applications. These materials offer unique properties for specific chip types.

Photolithography and Patterning

Photolithography is a critical step in chip fabrication. It uses light to transfer circuit patterns onto the silicon wafer.

The process starts by coating the wafer with a light-sensitive material called photoresist. A machine then projects the circuit pattern onto the coated wafer.

UV light or extreme ultraviolet (EUV) exposes specific areas of the photoresist. This exposure changes the chemical properties of the resist.

After exposure, the wafer undergoes development. This step removes either the exposed or unexposed areas, depending on the type of photoresist used.

The resulting pattern serves as a template for subsequent fabrication steps. It guides processes like etching and deposition.

Deposition and Doping Processes

Deposition adds new material layers to the wafer surface. Common methods include chemical vapor deposition (CVD) and physical vapor deposition (PVD).

These processes deposit thin films of various materials. Examples include insulators, conductors, and semiconductors.

Doping introduces impurities into the silicon to modify its electrical properties. It creates regions with different conductivity levels.

Ion implantation is a precise doping method. It accelerates dopant ions and implants them directly into the silicon.

Diffusion is another doping technique. It uses high temperatures to drive dopant atoms into the silicon structure.

Etching and Layer Formation

Etching removes specific areas of material from the wafer surface. It creates the intricate patterns needed for chip functionality.

Wet etching uses chemical solutions to dissolve unwanted material. Dry etching employs plasma or reactive gases to remove material.

Both methods can be isotropic (etching in all directions) or anisotropic (etching in specific directions).

Layer formation involves building up the chip’s structure. It combines deposition, doping, and etching processes.

Multiple layers of different materials form the complete chip. Each layer serves a specific purpose in the chip’s overall function.

Advanced Microchip Manufacturing and Industry Impact

Advanced microchip manufacturing involves cutting-edge technologies and global industry players. The process combines intricate production techniques, innovative packaging methods, and the expertise of major chipmakers worldwide.

Production Technologies and Scaling

Modern microchip production relies on advanced lithography techniques. Extreme ultraviolet (EUV) lithography enables the creation of smaller transistors on chips. This technology allows for more components on a single chip, boosting performance and energy efficiency.

Moore’s Law continues to drive chip scaling. Manufacturers aim to double transistor density every two years. This push for miniaturization presents challenges in heat management and quantum effects at nanoscale levels.

3D chip stacking is another key innovation. It allows for vertical integration of components, increasing chip density without shrinking transistor size. This technique improves performance and power efficiency in limited spaces.

Packaging and Integration of Microchips

Advanced packaging techniques are crucial for modern chips. Fan-out wafer-level packaging (FOWLP) reduces chip size and improves performance. It allows for better heat dissipation and power distribution.

System-in-Package (SiP) technology integrates multiple chips in a single package. This approach is vital for compact devices like smartphones. It enables the combination of processors, memory, and other components in one unit.

Chiplets represent a new paradigm in chip design. They allow manufacturers to combine different components made with various processes. This modular approach offers flexibility and cost-effectiveness in chip production.

Major Chipmakers and Global Foundries

Taiwan Semiconductor Manufacturing Company (TSMC) is a leading chip manufacturer. It produces advanced chips for companies like Apple, NVIDIA, and AMD. TSMC’s dominance in cutting-edge processes gives it a significant market share.

Intel focuses on both chip design and manufacturing. It aims to regain its leadership in advanced chip production. Intel’s investments in new fabs and technologies demonstrate its commitment to competing with TSMC.

Samsung is another major player in chip manufacturing. It produces chips for its own devices and offers foundry services to other companies. Samsung competes directly with TSMC in advanced chip production.

Global foundries like GlobalFoundries and UMC provide manufacturing services to various chip designers. These foundries specialize in specific processes and cater to diverse market needs.