Thermal pads and thermal paste are essential components in computer cooling systems. They facilitate the transfer of heat from processors and other components to heatsinks. Thermal pads are particularly useful in situations where there are gaps between components that require heat dissipation. The thickness of the pad can be critical for bridging the distance between a cooler and a heat-producing device, as thermal grease may not be effective when there is significant space between the surfaces.

Thermal pads are designed to fill larger spaces between heat-generating parts and cooling solutions, making them suitable for components like memory chips, voltage regulators, and other parts that don’t make direct contact with heatsinks. In contrast, thermal paste is more effective for direct contact between CPUs or GPUs and their coolers.

Choosing between thermal pads and thermal paste depends on the specific application. Pads are easier to apply, less messy, and tend to maintain their shape and position over time. However, thermal paste often provides superior heat transfer in direct-contact situations due to its ability to fill microscopic imperfections on surfaces.

Are Thermal Pads Worth Using?

This guide explains the benefits and drawbacks of using thermal pads, compares them to thermal paste, and provides advice on choosing the right thermal pad for your needs. We’ll also briefly discuss other cooling solutions to give you a complete overview of computer cooling options.

What are Thermal Pads?

Thermal pads are thermally conductive materials used to transfer heat between components and heatsinks. They are often made of silicone or other soft, flexible materials. They come in various thicknesses and sizes.

How Do Thermal Pads Work?

Like thermal paste, thermal pads fill gaps between surfaces. These gaps trap air, which is a poor heat conductor. Thermal pads conduct heat away from the component and into the heatsink.

When Are Thermal Pads Used?

Thermal pads are commonly used on components that don’t generate as much heat as a CPU or GPU. These include:

- VRMs (Voltage Regulator Modules): These components on the motherboard regulate power to the CPU.

- Memory Chips (RAM): These chips store data for your computer.

- SSDs (Solid State Drives): Some high-performance SSDs need cooling.

- Chipsets: These chips on the motherboard control communication between different parts of the system.

Advantages of Thermal Pads

- Easy to Apply: Thermal pads are much easier to apply than thermal paste. You just peel off a protective layer and place the pad on the component.

- No Mess: They are less messy than thermal paste. There’s no risk of spills or over-application.

- Reusable (Sometimes): Some thermal pads can be reused if they are not damaged.

Disadvantages of Thermal Pads

- Lower Thermal Conductivity: Thermal pads generally have lower thermal conductivity than high-quality thermal paste. This means they don’t transfer heat as efficiently.

- Thickness Issues: Using the wrong thickness of thermal pad can create a larger gap than intended, making cooling worse.

- Not Ideal for High-Heat Components: They are not recommended for high-heat components like CPUs or GPUs, where thermal paste provides much better performance.

Thermal Paste vs. Thermal Pads

Here’s a quick comparison:

| Feature | Thermal Paste | Thermal Pads |

|---|---|---|

| Thermal Conductivity | Higher | Lower |

| Application | More difficult | Easier |

| Messiness | More messy | Less messy |

| Best For | CPUs, GPUs | VRMs, memory, SSDs |

Are Thermal Pads Worth Using?

Yes, thermal pads are worth using in specific situations. They are a good choice for components that don’t generate extreme heat. They are also a good option when ease of application is a priority.

Choosing the Right Thermal Pad

- Thickness: It’s very important to use the correct thickness. Too thick or too thin will reduce cooling performance. Check the manufacturer’s specifications for your component.

- Thermal Conductivity: Look for pads with a higher thermal conductivity rating for better performance.

- Material: Silicone-based pads are common. Other materials offer better performance but may be more expensive.

When to Avoid Thermal Pads

Don’t use thermal pads on CPUs or GPUs unless specifically recommended by the manufacturer. Thermal paste is much better for these components.

Quick Tips for Using Thermal Pads

- Clean the surfaces before applying the pad.

- Remove any protective films from both sides of the pad.

- Apply even pressure when installing the heatsink.

Other Cooling Solutions

Besides thermal paste and pads, there are other cooling options. These include heatsinks, fans, and liquid cooling systems. Heatsinks are metal blocks that absorb heat. Fans move air across the heatsink to dissipate heat. Liquid cooling uses a liquid to transfer heat away from components. These solutions are often used in combination with thermal paste or pads for maximum cooling performance. Heatsinks are passive cooling solutions. They rely on natural air convection to dissipate heat. Fans provide active cooling by forcing air across the heatsink. This increases the rate of heat transfer. Liquid cooling is the most effective cooling solution. It can keep components much cooler than air cooling. But it is also more complex and expensive.

Key Takeaways

- Thermal pads excel at filling larger gaps between components and heatsinks

- Thermal paste performs better for direct contact between processors and coolers

- The choice between pads and paste depends on the specific cooling needs of each component

Thermal Management Basics

Thermal pads offer a convenient and mess-free way to improve heat transfer for certain computer components. While they don’t match the performance of high-quality thermal paste for high-heat applications like CPUs and GPUs, they are valuable for cooling other components like VRMs, memory chips, and SSDs.

Effective thermal management is crucial for electronic devices. It ensures optimal performance and longevity by regulating heat dissipation. Key components in this process include thermal interface materials, thermal paste, and thermal conductivity.

Understanding Thermal Interface Materials

Thermal interface materials (TIMs) play a vital role in heat transfer between electronic components and heat sinks. Thermal pads are a common type of TIM. These soft, pliable materials conform to surface irregularities, filling air gaps and enhancing thermal conductivity.

TIMs come in various forms:

- Thermal pads

- Thermal grease

- Phase change materials

- Thermal adhesives

Each type has specific applications based on factors like heat output, component size, and device design. Thermal pads excel in situations requiring gap filling and electrical insulation.

Comparison to Thermal Paste

Thermal paste and thermal pads serve similar functions but differ in application and performance. Thermal paste, also known as thermal grease, is a viscous substance applied directly to components.

Advantages of thermal paste:

- Higher thermal conductivity

- Thinner application possible

- Fills microscopic surface imperfections

Advantages of thermal pads:

- Easier to apply

- Reusable in some cases

- Better for uneven surfaces

Thermal paste typically offers better performance but requires careful application. Thermal pads are more user-friendly and suit a wider range of applications.

Importance of Thermal Conductivity

Thermal conductivity measures a material’s ability to transfer heat. It is a critical factor in choosing thermal interface materials. Higher thermal conductivity allows for more efficient heat dissipation.

Thermal conductivity is measured in watts per meter-kelvin (W/mK). Common values:

- Standard thermal pads: 1-5 W/mK

- High-performance thermal pads: 5-15 W/mK

- Thermal paste: 4-12 W/mK

Materials with higher thermal conductivity generally provide better heat transfer. However, other factors like thickness, pressure, and surface area also affect overall thermal performance.

Choosing the right thermal interface material involves balancing thermal conductivity with practical considerations such as ease of application and long-term stability.

Applications and Performance

Thermal pads serve various purposes in electronic devices. They provide efficient heat transfer and insulation in different applications, from personal computers to gaming consoles.

CPU and RAM Cooling Solutions

Thermal pads play a crucial role in CPU and RAM cooling. They fill gaps between components and heatsinks, ensuring optimal heat dissipation. For CPUs, thermal pads are sometimes used alongside thermal paste for enhanced cooling.

RAM modules often use thermal pads exclusively. These pads cover the entire surface of memory chips, providing consistent contact with heatspreaders. This method is especially effective for high-performance RAM that generates more heat.

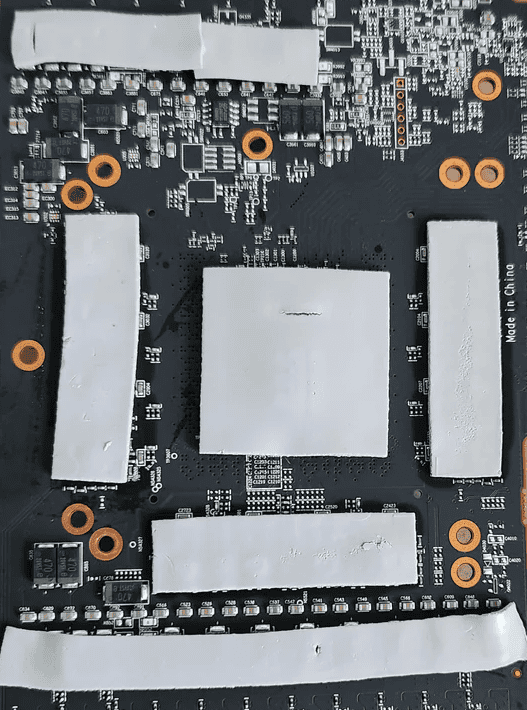

Some manufacturers, like EVGA, use thermal pads in their graphics cards. These pads cool various components on the PCB, including VRMs and VRAM chips.

Usage in Laptops and Game Consoles

Laptops and game consoles benefit greatly from thermal pads. In laptops, these pads are essential for cooling CPUs, GPUs, and other heat-generating components in tight spaces.

Thermal pads in laptops:

- Fill irregular gaps between components

- Provide electrical insulation

- Absorb vibrations

Game consoles like PlayStation and Xbox use thermal pads extensively. They help maintain consistent temperatures in compact enclosures, preventing overheating during extended gaming sessions.

Thermal pads in consoles are often pre-cut to fit specific components. This design ensures proper coverage and simplifies assembly and maintenance processes.

Selecting Thermal Pads for Electronics

Choosing the right thermal pad is crucial for optimal performance. Graphite thermal pads offer exceptional conductivity, making them ideal for high-performance applications. Silicone pads are popular in consumer electronics due to their flexibility and wide temperature range.

Key factors to consider when selecting thermal pads:

- Thermal conductivity (W/mK)

- Thickness

- Compressibility

- Operating temperature range

Thickness is particularly important. Too thin, and the pad may not fill gaps effectively. Too thick, and it might impede heat transfer. Most electronic applications use pads ranging from 0.5mm to 3mm thick.

Compressibility affects a pad’s ability to conform to surfaces. Softer pads generally provide better contact but may pump out over time. Firmer pads maintain their shape but require more pressure for effective contact.