Crimping Ethernet cables like Cat5, Cat6, and Cat7 can seem hard if you’re new to it, but it’s actually pretty simple. Using the right tools and techniques can save you time and money. This guide will take you through the steps needed to prepare, strip, and crimp your Ethernet cables efficiently. Start by setting up a clean, organized workspace to make the job easier. Gather your tools—a crimping tool, Ethernet cable, RJ45 connectors, and a wire stripper.

Strip around 2-3 inches of the outer jacket, making sure you do not cut the wires inside. It’s important to align and arrange the internal wires according to the wiring standards before putting them into the connector. Once inserted, push the wires into the connector and use your crimping tool to secure them. This will ensure a reliable connection that won’t easily come apart. Following these steps will make sure that your Ethernet cables will perform well in your network setup.

Tools and Materials Needed for Crimping

Crimping an Ethernet cable isn’t hard, but you need the right tools to do it. Here’s what you’ll need:

| Item | Description |

|---|---|

| Ethernet Cable | The cable you want to connect (Cat5e, Cat6, etc.). |

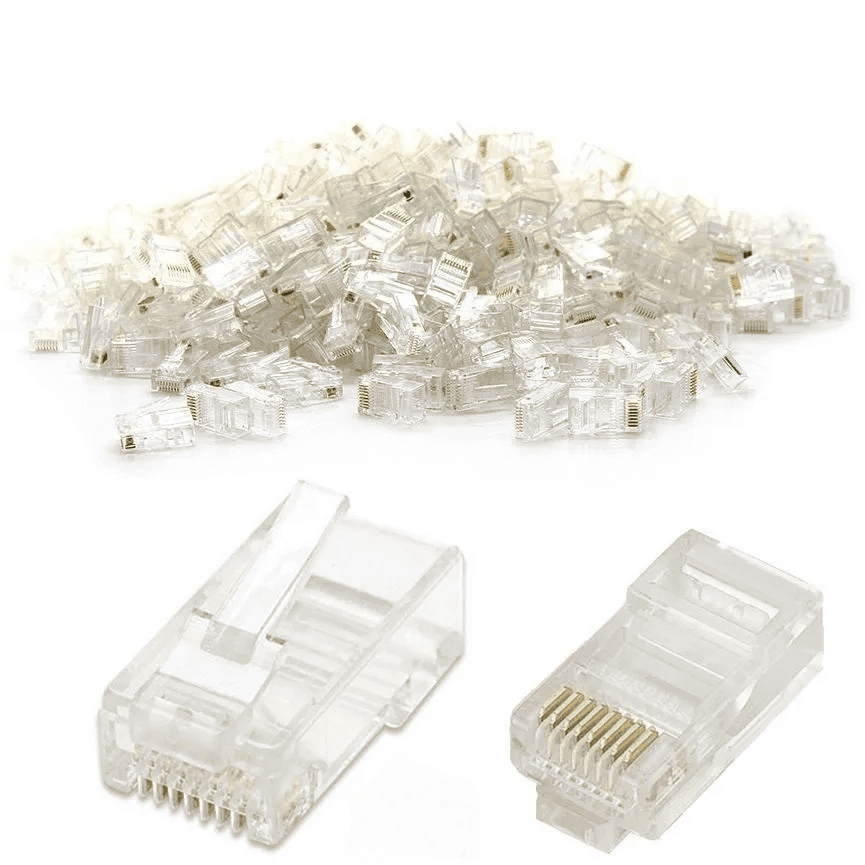

| RJ45 Connectors | Small plastic plugs that go on the end of the cable. |

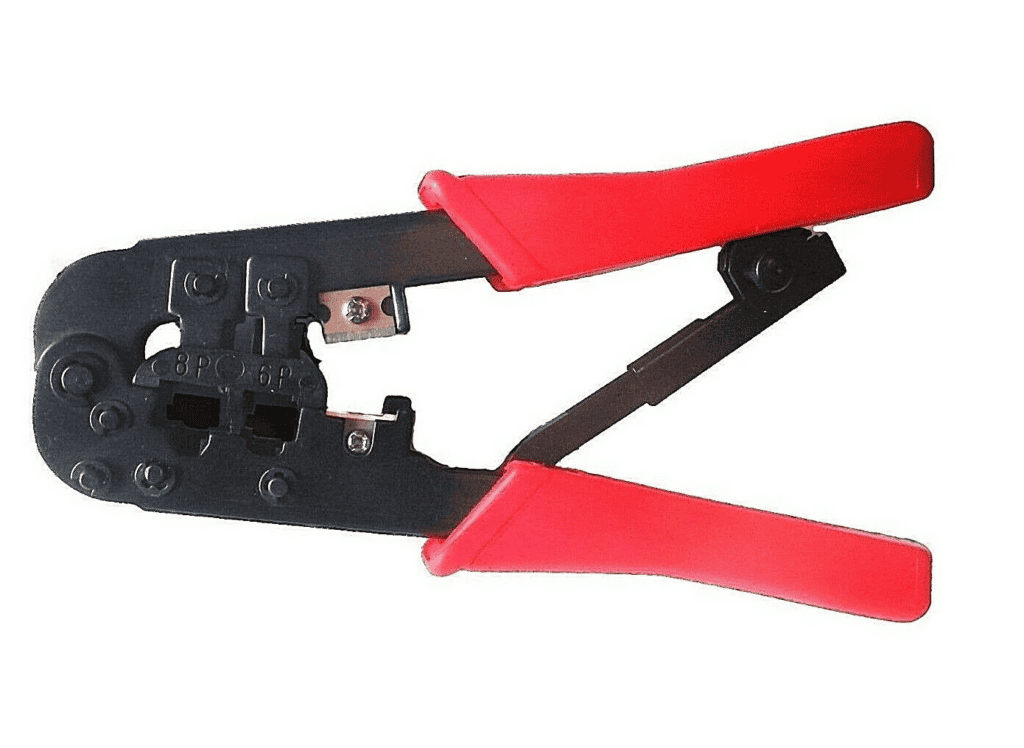

| Crimping Tool | Used to secure the connector to the cable. |

| Cable Stripper | Strips the outer jacket off the cable. Some crimping tools have a stripper built in. |

| Cable Tester (Optional) | Helpful for verifying the connection is good. |

Step 1: Prepare the Cable

Use the stripper to remove about an inch of the outer jacket from the end of the cable. Be careful not to nick the wires inside.

Step 2: Untwist and Arrange the Wires

You’ll find eight color-coded wires twisted in pairs. Untwist each pair, then straighten the wires and arrange them in the correct order:

- T568A Standard: White/Green, Green, White/Orange, Blue, White/Blue, Orange, White/Brown, Brown

- T568B Standard: White/Orange, Orange, White/Green, Blue, White/Blue, Green, White/Brown, Brown

T568B is the most common standard for home networks.

Step 3: Trim the Wires

Line up the wires evenly and trim them so they’re about half an inch long.

Step 4: Insert the Wires into the Connector

Carefully slide the wires into the RJ45 connector, making sure they stay in the correct order. Push them in until the ends touch the gold contacts in the connector. The cable’s jacket should be inside the connector’s back.

Step 5: Crimp the Connector

Place the connector in the crimping tool and squeeze firmly until you hear a click. This secures the wires in place.

Step 6: Test the Connection (Optional)

If you have a cable tester, plug the cable in and verify that all lights are on and in the correct order. If you don’t have a tester, try connecting the cable and see if it works.

Remember: Practice makes perfect. If your first attempt doesn’t work, don’t worry. Just try again!

Key Takeaways

- Strip around 2-3 inches of the outer jacket without damaging internal wires

- Align and insert wires into the connector properly

- Use a crimping tool to secure the wires and finish the job

Preparing to Crimp Ethernet Cable

Crimping an Ethernet cable requires understanding the cable categories and gathering the right tools. Clear steps for cutting, stripping, and sorting the cables will ensure an effective crimp.

Understanding Cable Categories

Ethernet cables come in different categories like Cat5, Cat6, and Cat7. Cat5e is an improved version of Cat5, providing better performance. Cat6 cables support higher bandwidth and faster speeds, while Cat7 offers even better shielding for higher signal quality.

- Cat5e: Up to 1 Gbps speed.

- Cat6: Up to 10 Gbps at shorter distances.

- Cat7: Similar to Cat6 but with enhanced shielding and performance.

Choosing the right cable depends on your network requirements. Newer categories are backward compatible, meaning they can work with older systems, but taking advantage of their full performance might require updated hardware.

Gathering Tools and Materials

To crimp an Ethernet cable, gather essential tools:

- Wire Cutters: For cutting cables to length.

- Wire Strippers: To remove the outer sheath.

- Crimping Tool: For attaching the RJ45 connectors.

- RJ45 Connectors: The plugs used to terminate the cables.

- Relief Boots: Optional, can protect the connectors.

Having a well-lit workspace is also important. Clean up any clutter to prevent mistakes. Laying out all tools and materials before starting will make the process smoother.

Cutting and Stripping the Cable

Start by cutting the Ethernet cable to your desired length using wire cutters.

- Cut straight across: Ensure a clean cut.

- Strip the outer sheath: Use the stripper to remove about an inch (25 mm) of the outer jacket, revealing the twisted pairs inside.

- Untwist pairs: Gently untwist and separate the wires.

Be careful not to nick or damage the wires when removing the sheath as this can affect performance. If the wires are damaged, cut and strip again.

Sorting and Aligning the Wires

Sorting and aligning the wires correctly is crucial for a proper connection.

- Arrange the wires: Follow the T-568B or T-568A wiring diagram. These standards dictate the order of the colored wires.

- Flat alignment: Once arranged, hold the wires between your fingers and straighten them. Scissors can trim any uneven ends.

- Insert into the connector: Push the wires into the RJ45 connector, ensuring each wire goes into its proper slot. The plastic clip should face down.

Make sure the outer sheath also enters the connector for extra support. Double-check the order of wires before crimping to avoid issues in the network connection.

Using the correct tools and following each step carefully will help ensure a successful and reliable Ethernet cable connection.

Frequently Asked Questions

This section provides clear and concise answers to common questions about crimping Cat5, Cat6, and Cat7 Ethernet cables.

What color codes are used for crimping Cat 5 cables?

For crimping Cat 5 cables, use the T568A or T568B standard. T568A uses green-white, green, orange-white, blue, blue-white, orange, brown-white, and brown. T568B uses orange-white, orange, green-white, blue, blue-white, green, brown-white, and brown.

Which RJ45 crimping tool is recommended for Ethernet cable assembly?

Use a high-quality RJ45 crimping tool for assembly. Klein Tools, TRENDnet, and VCELINK are well-regarded brands. These tools ensure precise and reliable crimps, reducing the risk of connection failures.

How do you properly connect a Cat6 cable to an RJ45 socket?

First, strip about an inch of the cable jacket. Untwist the pairs and arrange them as per the T568A or T568B standard. Insert wires into the RJ45 connector, ensuring each wire reaches the end. Use a crimping tool to secure the connection.

What are the steps to crimp Ethernet cables with precision?

Prepare your tools and cut the cable to the desired length. Strip the jacket and untwist the pairs. Align wires in the correct sequence (T568A or T568B). Insert wires into the connector, ensuring they reach the end. Use a crimping tool to crimp and test the cable for continuity.

Is it possible to crimp an Ethernet cable without a crimper, and how?

Yes, it is possible. Strip the cable jacket and untwist the pairs. Arrange the wires in the correct sequence. Use a flat-head screwdriver to push each wire into the connector. Press down on the pins to secure the wires. Note, this method is less reliable than using a crimper.

Can Cat6 connectors be utilized on a Cat7 cable, and are there any limitations?

Yes, Cat6 connectors can be used on Cat7 cables. However, this may limit the cable’s performance to that of Cat6. Ensure the connector’s internal structure is compatible with the thicker gauge of Cat7 wires for a secure fit.