Gold extraction from old electronics is a complex process that requires specialized knowledge and equipment. The process involves several steps, including disassembly, chemical treatment, and refining to separate the gold from other materials. While it may seem tempting to try this at home, it’s not recommended due to safety risks and the need for proper handling of hazardous chemicals.

Electronic devices contain small amounts of gold in their components. A single smartphone, for example, has about 0.034 grams of gold. This means that extracting a significant amount of gold requires processing large volumes of e-waste, which can be time-consuming and challenging.

Professional gold recovery methods often use chemicals like aqua regia or cyanide to dissolve the gold. After dissolution, the gold is separated from the solution and refined. These processes require careful handling and proper safety measures to avoid health and environmental risks.

Extracting Gold from Old Electronics: A Complex Process

Electronic waste, or e-waste, contains valuable metals like gold. Recovering this gold is important for environmental and economic reasons. But extracting gold from old electronics is a complex process that requires specialized techniques.

Why Extract Gold from E-Waste?

- Resource Conservation: Gold is a finite resource. Recycling gold from e-waste reduces the need to mine new gold, conserving natural resources.

- Environmental Protection: E-waste contains hazardous materials. Properly recycling e-waste prevents these materials from polluting the environment.

- Economic Benefits: Recovering gold from e-waste creates jobs and contributes to the economy.

The Challenges of Gold Extraction

Extracting gold from e-waste is challenging because:

- Low Concentrations: Electronics contain small amounts of gold. It requires processing large volumes of e-waste to recover a significant amount of gold.

- Complex Composition: E-waste contains a mix of materials, making it difficult to isolate the gold.

- Hazardous Materials: Some e-waste contains hazardous materials that require careful handling and disposal.

Steps in Gold Extraction

- Collection and Sorting: E-waste is collected and sorted to separate different types of devices and components.

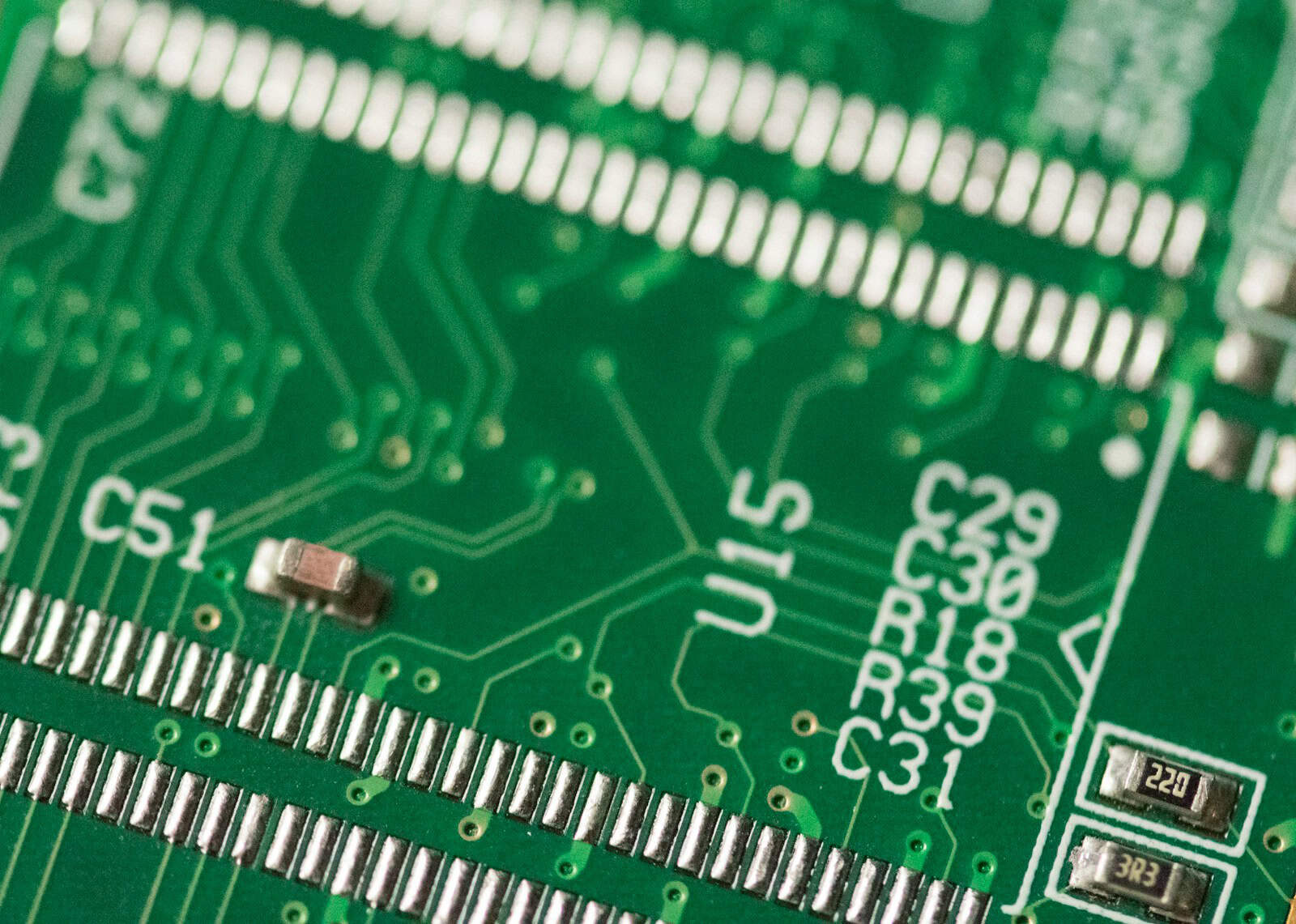

- Dismantling: Devices are dismantled to remove components that contain gold, such as circuit boards and connectors.

- Mechanical Processing: Components are shredded or crushed to reduce their size.

- Chemical Processing: Several chemical processes can be used to extract gold, including:

- Leaching: Using chemicals like cyanide or aqua regia to dissolve the gold.

- Electrolysis: Using an electrical current to separate the gold from other metals.

- Refining: The extracted gold is further refined to remove impurities and achieve high purity.

Environmental and Safety Concerns

Traditional gold extraction methods often involve hazardous chemicals that can harm the environment and human health. Researchers are developing more sustainable and eco-friendly methods, such as using bio-leaching with microorganisms or less toxic chemicals.

The Future of Gold Recycling

As technology advances, the amount of gold in e-waste is likely to increase. This makes it even more important to develop efficient and sustainable methods for gold extraction. Researchers are exploring new techniques, such as using nanotechnology or supercritical fluids, to improve the efficiency and reduce the environmental impact of gold recycling.

The Importance of Responsible E-Waste Recycling

Proper e-waste recycling is crucial for protecting the environment and human health. Here are some ways you can contribute:

- Recycle your old electronics: Don’t throw old electronics in the trash. Take them to a certified e-waste recycler.

- Choose responsible recyclers: Look for recyclers that are certified and follow environmentally sound practices.

- Support legislation: Support legislation that promotes responsible e-waste management and recycling.

- Reduce consumption: Consider repairing or upgrading your electronics instead of replacing them, reducing the amount of e-waste generated.

Key Takeaways

- Gold extraction from electronics involves complex processes and specialized equipment

- Large volumes of e-waste are needed to recover significant amounts of gold

- Professional methods use chemical treatments to dissolve and refine the gold

Understanding E-Waste and Gold Content

Extracting gold from old electronics is a complex and challenging process, but it’s crucial for environmental protection, resource conservation, and economic development. By understanding the steps involved and the importance of responsible recycling, we can all contribute to a more sustainable future.

Electronic waste contains valuable metals, including gold. The extraction process is complex and impacts the environment. Proper handling of e-waste is crucial for recovering precious materials and reducing pollution.

Composition of Electronic Waste

E-waste comprises a wide range of discarded electronic devices. These include computers, cell phones, and other gadgets. The components in e-waste vary, but often contain:

- Circuit boards

- Motherboards

- Central processing units (CPUs)

- Random access memory (RAM) chips

- Hard drives

- Internal modems

These parts contain precious metals like gold. Other valuable materials found in e-waste include:

- Palladium

- Tantalum

- Neodymium

- Cobalt

- Aluminum

The composition of e-waste makes it a potential source of valuable resources if properly recycled.

Gold in Electronic Devices

Gold plays a crucial role in electronic devices due to its excellent conductivity. It is used in:

- Circuit boards

- Connectors

- CPU components

The amount of gold in devices varies. A typical cell phone contains about 0.034 grams of gold. Larger devices like computers may have more. Computer motherboards can yield significant amounts of gold.

Gold recovery from e-waste is becoming more profitable. New methods make the process more efficient and cost-effective. This “urban mining” could be a sustainable source of gold in the future.

Environmental Impact of E-Waste

Improper disposal of e-waste poses serious environmental risks. When electronics end up in landfills, toxic materials can leach into soil and water. This pollution threatens ecosystems and human health.

Recycling e-waste reduces these risks. It also conserves natural resources. New extraction methods are more environmentally friendly. They use fewer harsh chemicals and produce less waste.

Proper e-waste management is essential. It helps recover valuable materials and protects the environment. Consumers and businesses play a key role in responsible e-waste disposal.

The Gold Recovery Process

Extracting gold from electronic waste involves complex chemical and mechanical processes. These methods require careful preparation, safety measures, and specialized techniques to efficiently recover precious metals.

Preparation and Safety

Gold recovery from electronics demands proper safety precautions. Workers must wear protective gear including gloves, goggles, and respirators. Adequate ventilation is crucial to prevent exposure to toxic fumes.

First aid supplies should be readily available. Skin burns from chemicals require immediate treatment. Safe handling and storage of acids and other reagents is essential.

Proper disposal of waste materials is critical to prevent environmental contamination. Workers should be trained in emergency procedures and chemical spill containment.

Chemical Treatment Methods

The primary chemical method for gold extraction is the use of aqua regia, a mixture of hydrochloric and nitric acids. This powerful solution dissolves gold but not other metals.

Steps in the chemical process:

- Dissolve gold in aqua regia

- Filter the solution

- Precipitate gold using reducing agents like sodium metabisulfite

Newer methods use less toxic chemicals like thiosulfate or halide solutions. These alternatives are becoming more popular due to environmental concerns.

Mechanical Processing and Separation

Mechanical processing breaks down e-waste into smaller pieces. This step increases surface area for chemical reactions.

Common mechanical techniques include:

- Shredding

- Grinding

- Magnetic separation to remove ferrous metals

- Eddy current separation for non-ferrous metals

Sieving and density separation help concentrate gold-bearing materials. Flotation can be used to separate gold from other metals based on surface properties.

Purification and Melting Procedures

Final purification often involves electrorefining. This process uses an electric current to deposit pure gold onto cathodes.

Gold dust and flakes are melted using high-temperature furnaces or propane torches. Borax is added as a flux to remove impurities.

The molten gold is poured into molds to form bars or ingots. These are then assayed to determine purity.

Refining can achieve purities up to 99.999%. The final product is typically 24-karat gold ready for resale or industrial use.